Potential of Mollusca Shells as Raw Material for Bioceramics and Calcium

By. Azizah - 06 Sep 2025

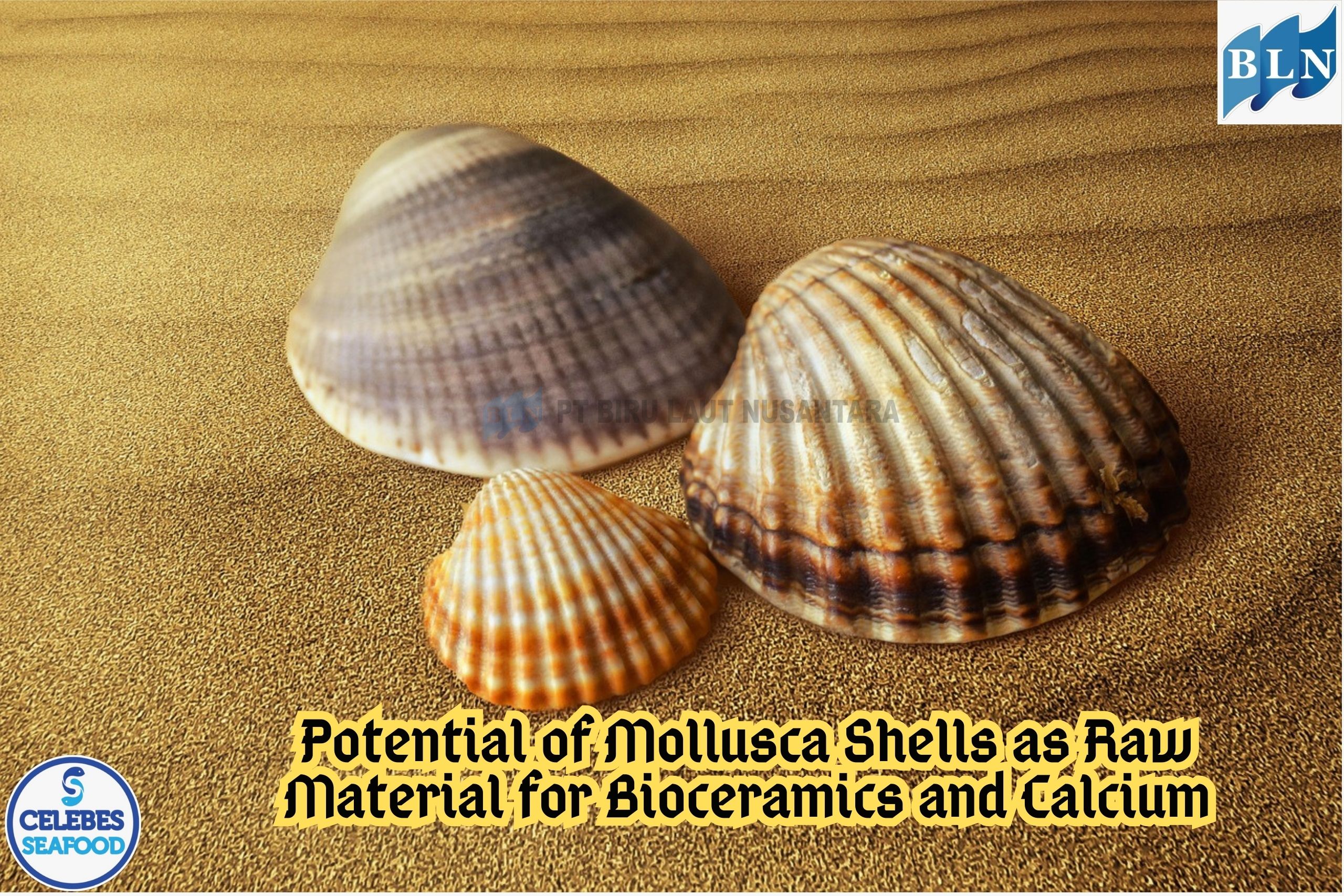

lautnusantara.com Mollusca shells are abundant fishery waste, yet they are often underutilized. The main component of shells is calcium carbonate (CaCO₃), which can be converted into calcium oxide (CaO) or used as a base material for bioceramics. Calcium-based bioceramics have wide applications, particularly in dentistry, orthopedics, and the food industry. This article discusses the potential of mollusca shells as an alternative source of natural calcium as well as an environmentally friendly raw material for bioceramics.

Introduction

Mollusca, especially bivalves (clams, oysters, mussels) and gastropods (marine snails), produce shells as part of their defense system. In many coastal areas, mollusca shells accumulate as waste due to human consumption. If not managed properly, this waste can cause environmental pollution.

On the other hand, mollusca shells contain more than 90% calcium carbonate, in the form of aragonite or calcite crystals, along with small amounts of protein and other minerals. This composition provides high potential for shells to serve as an alternative raw material for bioceramics and calcium products.

Chemical Composition of Mollusca Shells

Generally, mollusca shells are composed of:

-

Calcium carbonate (CaCO₃): 90–95%

-

Organic proteins: 1–5%

-

Magnesium, strontium, and other minor minerals

The high calcium content allows shells to be converted into CaO through calcination, which can then be applied in various industrial and health-related uses.

Applications in Bioceramics

Bioceramics are ceramic-based materials used for biomedical applications. Mollusca shells, after being processed into calcium phosphate or hydroxyapatite (HA), can be used as:

-

Bone implants – due to their biocompatibility and osteoconductive properties.

-

Dental fillers – as substitutes for dentin or enamel.

-

Medical implant coatings – to improve tissue bonding with metallic implants.

Several studies have shown that hydroxyapatite extracted from mollusca shells has comparable quality to commercial synthetic products.

Applications as a Calcium Source

Beyond biomedical applications, mollusca shells can also serve as a calcium source in:

-

Food industry – as calcium fortification in dairy products, beverages, or supplements.

-

Agriculture – as lime fertilizer to improve soil pH.

-

Animal husbandry – as feed additive for poultry to strengthen eggshells.

The main advantages of calcium derived from mollusca shells are its abundance, low cost, and eco-friendliness.

Challenges and Prospects

Despite their great potential, the utilization of mollusca shells still faces several challenges, including:

-

Processing technology that requires efficient calcination methods.

-

Quality standardization for biomedical applications must meet strict clinical requirements.

-

Lack of awareness in coastal communities about the economic value of shell waste.

However, with advances in material technology and increasing demand for bioceramic materials and natural calcium supplements, the prospects for utilizing mollusca shells are highly promising.

If you are interested in our Red Emperor Fillet Skin On Red Snapper Fillet Skin On please do not hesitate to contact us through email and/or whatsapp.