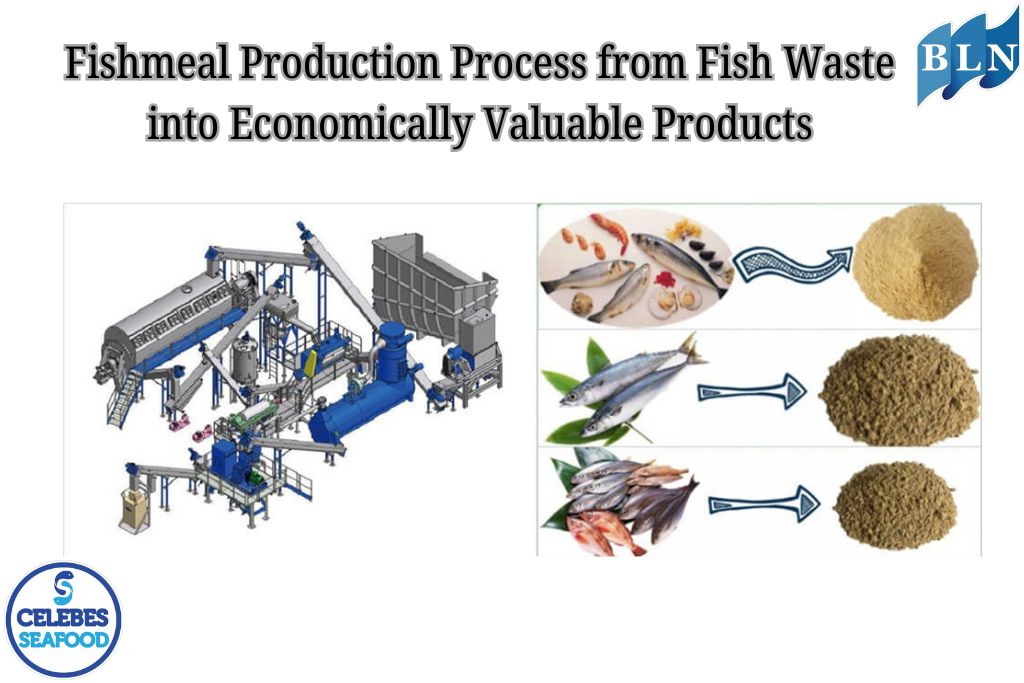

Fishmeal Production Process from Fish Waste into Economically Valuable Products

By. Amma - 03 Jun 2025

lautnusantara.com Utilization of fish waste into fishmeal is one effective way to increase economic value and reduce environmental impact. This process not only produces a product rich in nutrients, but also contributes to the sustainability of the fisheries industry. The following are the main steps in the process of making fishmeal from fish waste:

1. Collection and Sorting of Fish Waste

Fish waste that can be used includes heads, bones, stomach contents, skin, and other parts that are not utilized from the fish processing process. This waste must be collected immediately after being obtained to prevent rotting. After being collected, sort it to separate non-fish materials such as plastic or other foreign objects.

2. Washing

The sorted fish waste is then washed thoroughly with running water. The purpose of washing is to remove dirt, blood residue, and mucus that sticks. Effective washing will help reduce the fishy smell and improve the quality of the final fishmeal.

3. Size Reduction (Grinding/Crushing)

To speed up the drying and extraction process, fish waste needs to be reduced in size using a grinding or crushing machine. The smaller the particle size, the more efficient the next process.

4. Cooking

This stage involves cooking fish waste with steam or dry heat at a temperature of around 80-100°C for 15-30 minutes. Cooking aims to:

- Coagulate protein: Make protein coagulate so that it is easy to separate from water and fat.

- Sterilization: Kill pathogenic bacteria and other microorganisms that can cause spoilage.

- Separating fat: Heat will help release fat from fish tissue.

5. Pressing

After cooking, the cooked fish mass is then pressed using a screw press to separate the solids (cake) from the liquid (liquor) containing water, fat, and dissolved protein. This liquid is often called "stickwater".

6. Drying

The solid cake from pressing contains a high water content and needs to be dried to prevent microbial growth and extend the shelf life. Common drying methods include:

- Hot air dryer: Uses a hot air stream to evaporate water.

- Vacuum dryer: More efficient and suitable for products that are sensitive to high heat.

- Sun drying: A cheaper traditional method but takes longer and is highly dependent on the weather. The target water content in fishmeal is usually below 10%.

7. Milling / Grinding

Dried fishmeal is still in the form of lumps or flakes. The next stage is grinding using a grinding machine (hammer mill) until it reaches the desired particle size, usually in the form of a fine powder. The fineness of the flour will affect the absorption capacity and ease of mixing in the feed.

8. Sieving

After milling, fishmeal can be sieved to ensure uniform particle size and remove lumps or particles that are too large.

9. Packaging

The finished fishmeal is then packed in sacks or tightly closed containers to protect against moisture, contamination, and damage during storage and transportation.

Economically Valuable Products

Fishmeal is a product with high economic value due to its high protein content and complete essential amino acid profile. This product is widely used as:

- Raw material for animal feed: Especially for aquaculture feed (shrimp, fish), poultry (chicken, duck), and pets (dogs, cats).

- Organic fertilizer: Although less optimal than its use as feed, fishmeal can also be used as a nitrogen-rich fertilizer.

By processing fish waste into fishmeal, we not only reduce waste and potential environmental pollution, but also create a new source of income for the community and the fisheries industry.

If you are interested in our Barramundi Fillet Skin On / Barramundi Fillet Skinless Tyger Style, Barramundi Fillet Skinless Tiger Style please do not hesitate to contact us through email and/or whatsapp.

.jpg)